Equivalent Durability Test of Component Road Load

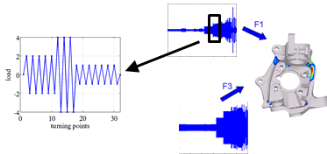

The core of component DV test design is o reproduce the dynamic response ( strain, acceleration, etc. ) and fatigue damage caused by complex load in the actual vehicle assembly environment and the actual road conditions and shorten the test time as much as possible, based on bench load of less degree of freedom ( single axis or multi-axis ) .

In setting the loading conditions and driving signals of the component bench test, it is usually necessary to substitute the simple load condition of the low degree of freedom bench for the original input load with high degree of freedom, where the principle is that the loading conditions of the bench can produce the same fatigue hot spot and the same damage on the components, but will not introduce new fatigue hot spots.

How to reproduce the fatigue damage of component under actual loads with the simplified bench loading is the engineering challenge that a vehicle factory is facing when designing the component DV test. With rich engineering experience in the component DV test design and the use of load decomposition and identification ( multi - body dynamics or True - Load )and finite element analysis, TS Engineering can help customers to develop DV test loading schemes under definite test bench equipment conditions ( installation and loading point, number of cylinders, working direction of dynamic cylinder, loading capacity, etc. ).